ER 308LSi

Alloy ER308LSi Welding data

Weld Process :

Used for Mig, Tig & Submerged arc

Deposited All Weld Metal Properties:

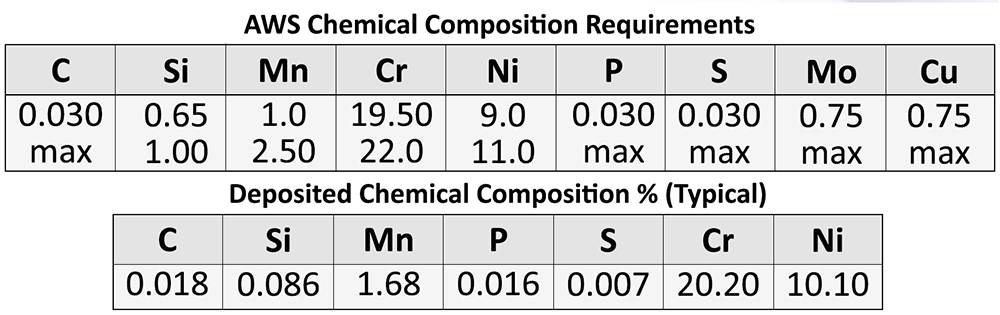

Data is typical for ER308LSi weld metal deposited by mig using Argon+2% oxygen and Tig using Argon as the shielding gas. Data on Sub-arc is not presented, as sub-arc is dependent on the type of flux used.

Application:

ER308Si is suitable for joining stainless steel of the 304 type and 308 types.welding speed is higher that 308 or 308L due to improved weldability of the weld metal.

Mechnical Properties (R.T.):

Yield strength > 380 MPa

Tensile strength > 610 MPa

Elongation > 39%

Reduction of area > 65%

Impact value > -196°C (35-55 Joules)

Type of Filler wire

GMAW ” Mig Filler wire”

Diameter Range

0.80-1.6mm

0.030″-1/16″

GTAW ” Tig Process ”

Diameter Range

1.60-4.00mm

1/16″-5/32″

Submerged Arc Welding

Diameter Range

1.60-4.00mm

1/16″-5/32″

Contact:

Tel: +90 232 422 22 22

WhatsApp: +90530 5707355

E-Mails:

info@ankawelding.com.tr

export@anlaweldiing.com.tr

Address:

ANKA KAYNAK ELEKT. SAN. A.Ş.

Küner Mah. Çevreyolu Bulv. 226/A

35470 Menderes/İZMİR/TÜRKİYE